Adapting the diesel engine to the tiller

Before we start, this engine has had some bad reviews that should be discussed. After using it for three seasons now, we know why. A diesel engine is different than a gasoline engine in every way, & thus cannot be operated in the same manner. There is simply a learning curve involved.

Some bad reviews claim the engine leaked diesel & ran badly upon initial startup. That is because the first time the engine is run, the fuel system needs to be bled. This is standard on any injected engine (no carburetor here folks). This process only takes a few minutes & is outlined in the instruction manual.

Others have extreme difficulty starting the engine. This is due to the startup procedure that must be followed to a tee. Set throttle to half, slowly pull the string until great resistance is met, allow string to retract gently, DECOMPRESS the engine by pushing the decompression lever down, then start. If it's really cold & hasn't been run today, 1/2cc/mL (documentation list 1cc/mL) of 10w30 motor oil can be injected with a syringe into the capped hole labeled "oil" on the top of the engine.

Bottom line, learn how to operate this engine properly & avoid the problems others claim to have had.

Getting started on the repower, a few modifications must be made. This starts with the pulley that mounts to the crankshaft. The original engine has a 3/4" shaft, & the new diesel engine comes with a 20mm shaft (larger than 3/4"). The pulley must be bored out by a machine shop. This cost us $20usd.

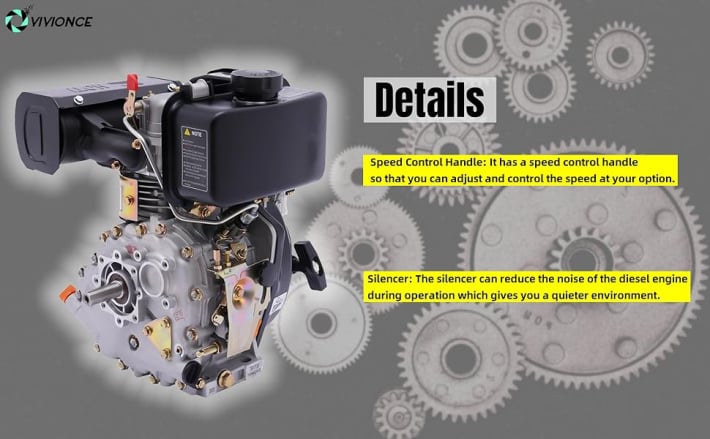

The engine is governed & has two ways to set the throttle, a manual method (knob on side of engine), & a way to use the cable from the original tiller. We use the knob exclusively (although if something catastrophic were to occur, there is no way to shut it down without reaching down to the engine).

The original engine had an emergency shutoff that required the operator to hold down one of the levers on the tillers handles while going forward. This was achieved electrically by killing the ignition when both levers on the handles were released. The new diesel engine does not use electricity for any of its functions, & therefore the safeties are disabled after the swap.

The bolts that mount the engine to the tiller are metric, so these bolts must be purchased. Tractor Supply had them for next to nothing.

The bolt holes in the weight that is mounted to the bottom of the original engine don't EXACTLY line up, but it's really close. Drilling them out just a bit larger makes it fit up nicely. The diesel engine weighs significantly more than the original gasoline engine in the first place, so this modification may not be absolutely necessary, but in our experience the extra weight helps the tiller significantly.

It is important that the engine be broken in properly. This requires running it for 20 hours under very light load. This is accomplished by running at half throttle for that amount of time, occasionally ramping it up & driving it around without actually tilling. It is best to shut it down & let the engine cool a few times during this period. Change the oil after break in.

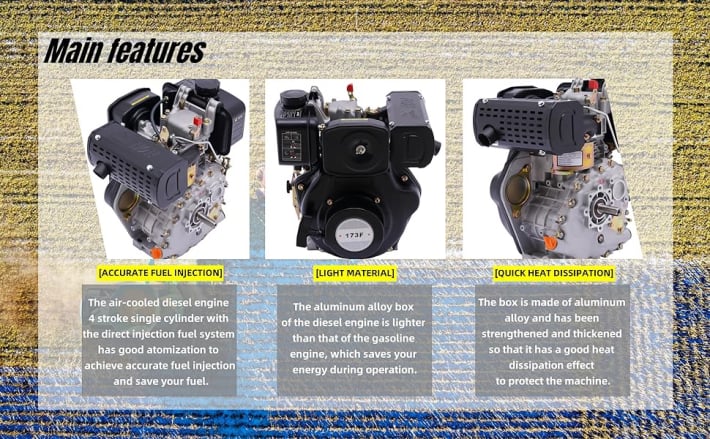

The original engine could have been either a 7hp or 8hp briggs or kohler (we have had all configurations for many years). The concept of rating constant rpm engines (especially engines that operate under heavy load) is not very useful. Our 7hp briggs felt significantly more powerful than the 8hp version we had of the same year model. The new diesel engine is rated at 3.6kw (a more useful number as it accounts for horse power & torque), which equates to about 6 horse power. That being said, the diesel engine digs WAY deeper & NEVER bogs down. It is an extremely powerful engine!

All great things have their share of pitfalls, so here they are:

As with any compression (diesel) engine, throttle response is very slow. This makes no difference at a constant rpm, but it doesn't like hitting large roots where the governor has to attempt to compensate. It will power right through it, but may blow a bit of diesel smoke & make the tiller jump.

The startup & shutdown procedure both require about 5 minutes.

Being injected, it is strongly advised not to run it out of fuel. This would require bleeding the fuel system again. Also, when it runs out of fuel it tends to die violently with a few burst of fire out the muffler. Just keep it from running out of fuel.

The pictures at the top of this page were taken of the tiller during it's 3rd season after weeks of hard work. It had been through hell, with around 70 hours of operation after being serviced right out of winter. This was purposeful so it could be viewed objectively rather than all cleaned up. We have put hundreds of hours on this engine in a three year period, working acres of land during all seasons including winter.

For the record, we have absolutely no affiliation with anyone selling this engine, & have absolutely nothing to gain by pushing it to others. This has been nothing more than an accounting of our personal experience with fixing up an otherwise useless machine.